What is

Automated Ball Indentation (ABI)®?

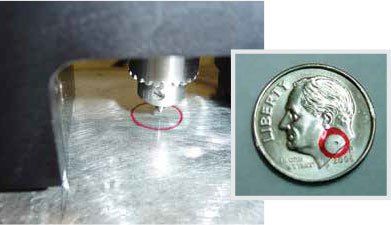

ABI® is a nondestructive mechanical testing technique for determining tensile and fracture toughness properties. It is based on progressive indentation with intermediate partial unloadings until the maximum depth (maximum strain) is reached, and then the indenter is fully unloaded. The ABI® test is a macroscopic (bulk) technique that measures the properties on a small volume of material.

- Ball indentations are shallow, with smooth edges and produce compressive stresses in the material that retard crack initiation

- The remaining ABI® depression is similar to one from shot-peening or sand blasting.

Designed for Quick Turn Field Testing

The Automated Ball Indentation® technology provides in-situ testing on in-service components to measure key mechanical properties including yield strength, flow properties, strain hardening parameters, and fracture toughness of ferritic steels.

- 5.5” outer diameter (OD) and larger pipes

- 12” long sections and larger

- Compression station piping

If your testing needs require specialized applications, our team can work with you to develop a bespoke testing system.