AI? ML? Digital Twins? They all Need Physical Data for Optimal Asset Integrity Results

AI? ML? Digital Twins? They all Need Physical Data for Optimal Asset Integrity Results

By: Clark Ellis, Senior Vice President & Fahmy Haggag, Chief Engineer, ABI® Technology

Artificial Intelligence, Machine Learning, Digital Twin…it’s hard to consume any amount of industry news without encountering one or all of these terms. Every company involved in the oil and gas industry (or any industry for that matter) needs to figure out what AI “means” to their business.

AI spending (includes Machine Learning or ML) related to oil and gas is projected to grow from approximately $3.5 billion this year, to almost $6.5 billion by 2030[1]. The Digital Twin market is expected to increase from $1.2 billion in 2024 to almost $3 billion by 2032[2].

AI uses powerful technology to take known information about a pipeline or a production process and project how those assets will perform in the future. Its results are essentially probabilistic representations of the core information that the model can access. They are, therefore, sensitive to the quality and quantity of the underlying true or deterministic data about the pipeline, pressure vessel, storage tank, or other structure. As more asset management departments at major oil and gas and pipeline operators use AI to improve their predictive models for proactive maintenance and repairs, the underlying physical data of the assets will increase in importance.

Knowing the material grade and full tensile properties is table stakes in assessing the asset’s viability to operate at the preferred production values. These measures help asset managers understand how the pipeline or vessel will perform under normal operating conditions over time. To have a full picture of the asset’s fitness for service, fracture mechanics, and particularly, fracture toughness is vital. Fracture toughness indicates the material’s resistance to crack propagation under a given stress intensity factor. Fracture toughness is required for Level 3 API 579 FFS/ASME-FFS-1[3].

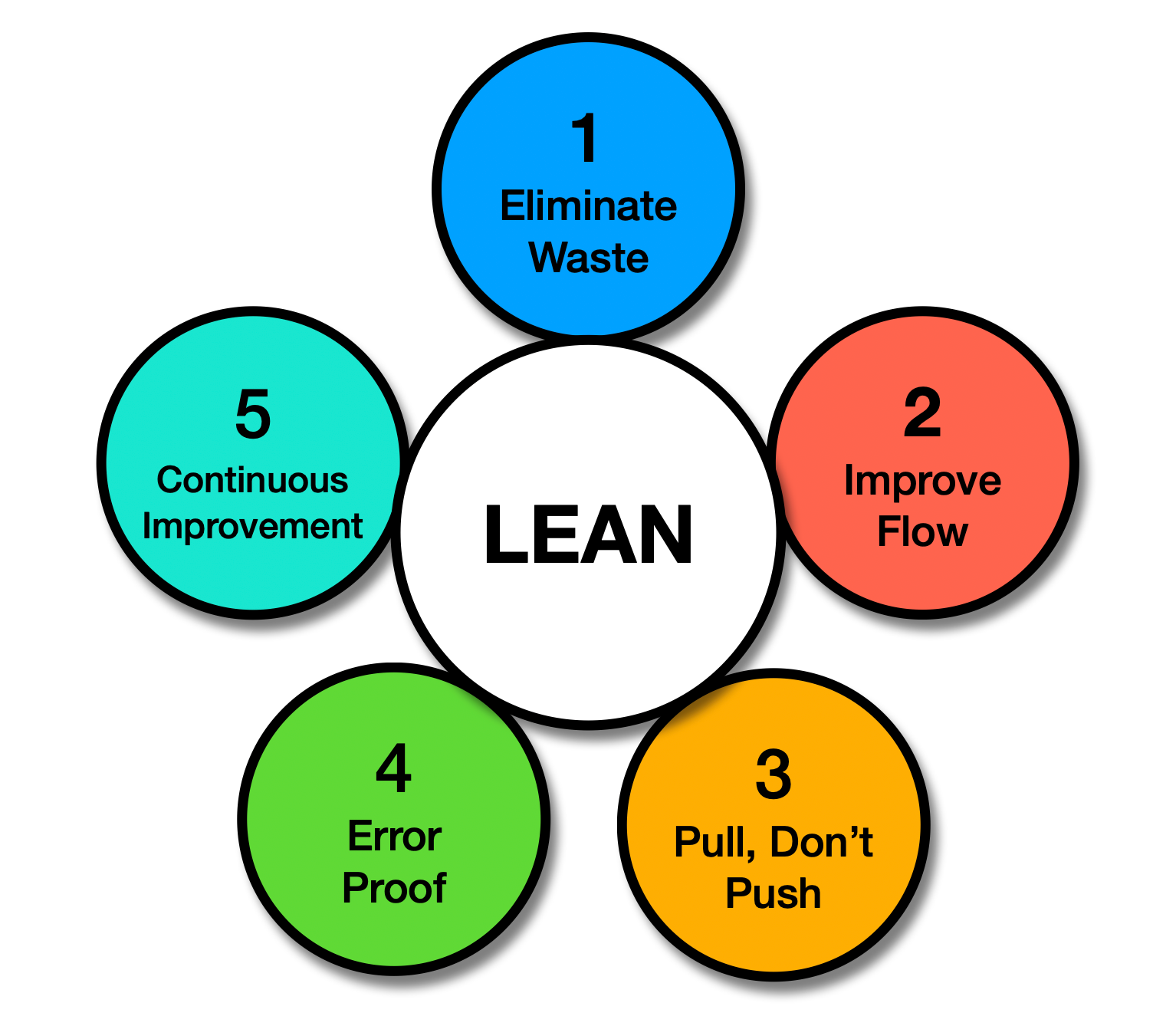

Cost and resources have traditionally been a major barrier to asset owners being able to do more testing on their assets. These barriers still exist to approximately the same degree with destructive testing, where samples of the asset in question must be cut out, taken to a lab, and tested. However, the growth of non-destructive testing (NDT) methods and equipment has shifted the cost and resource equation. Being able to increase testing frequency by as little as 10% can have a significant impact on the quality and accuracy of AI and ML models.

The data produced by NDT methods in the field provides a high-quality ground truth about the physical state of the assets. It also allows the models to be verifiable and auditable, which is important for regulatory acceptance. Overall, controlled deterministic data helps the models do a better job of generalizing across assets because they minimize training on impure, biased, or uncertain data.

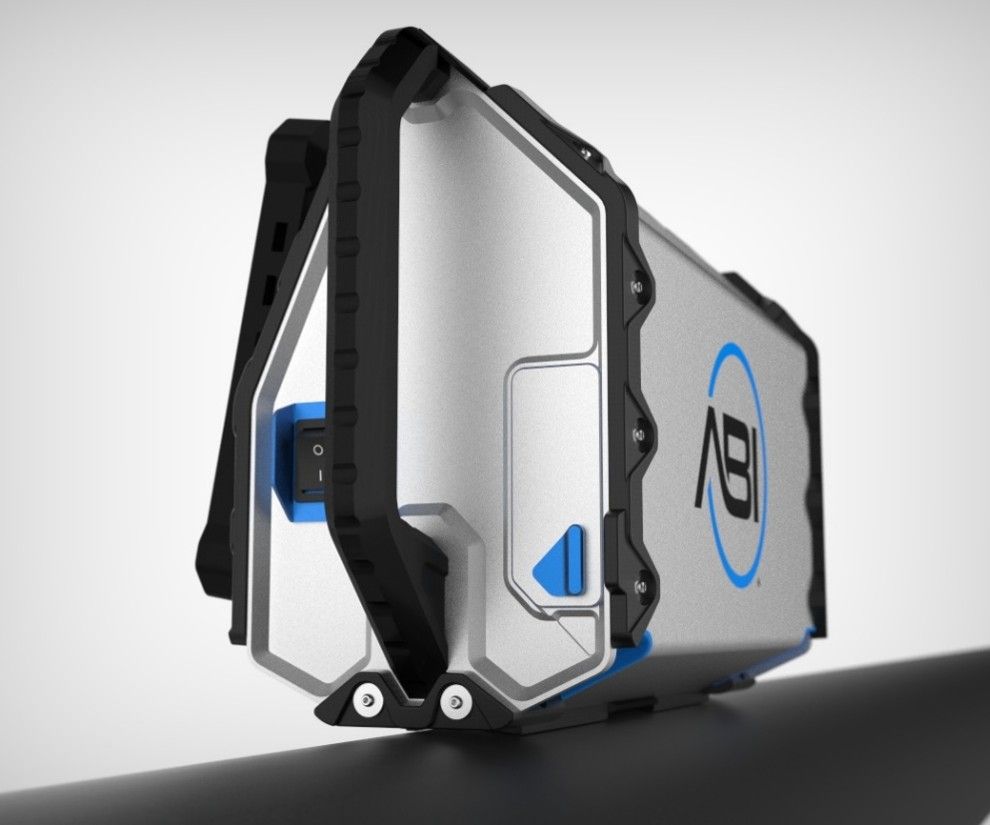

ABI® Technology provides asset integrity management teams with a quick and cost-effective means of generating physical (deterministic) tensile and, uniquely, fracture toughness, to improve AI, ML, and Digital Twin model accuracy.

Once the test area is exposed and polished, the ABI® Technology test is completed in 15-20 minutes, and the data can be instantly injected by the asset integrity model. Also designed for use by rope access teams, the ABI® system can eliminate the cost, time, and danger of building scaffolding. Most importantly, the ABI® test prevents incredibly costly shutdowns since the tests are performed non-destructively, in situ, as the asset/system continues operation. When compared with destructive testing, this can result in tens of thousands of dollars to millions of dollars in savings.

The speed, cost, and flexibility of the ABI® Technology tool can allow a higher physical testing frequency. This creates new data analysis opportunities driven by the AI/ML analytics and represented in Digital Twin models. As automated, probabilistic analytics continue to grow, ensuring those models are grounded in current, accurate, real-world physical data is critically important.

ABI® Technology leads the way in enabling asset integrity managers to have the accurate data they need to help their organizations achieve the highest productivity while assuring safety.

----------------------------------------------------------------------------------------------

[1] https://www.globenewswire.com/news-release/2025/04/29/3070057/0/en/AI-in-Oil-Gas-Market-Worth-3-54-Billion-in-2025-Revenues-Forecast-to-Reach-6-4-Billion-by-2030.html

[2] https://www.datamintelligence.com/research-report/digital-twins-in-the-oil-and-gas-market

[3] https://inspectioneering.com/content/2019-10-24/8815/fitness-for-service-the-users-guide-to-api-579-1ffs-1