Combining LEAN and NDT for Faster, More Effective Turnarounds

Combining LEAN and NDT for Faster, More Effective Turnarounds

By Clark Ellis, SVP ABI Technology

Introduction: A LEAN Lens for Turnarounds

Few events in oil and gas are as costly and complex as facility turnarounds, whether offshore, refineries, gas plants, or petrochemical plants. Each day offline can mean millions of dollars in lost production, while hundreds of workers inspect, repair, and restart critical equipment. Turnarounds are necessary, but their duration and scope often expand due to inefficiencies in inspection and decision-making.

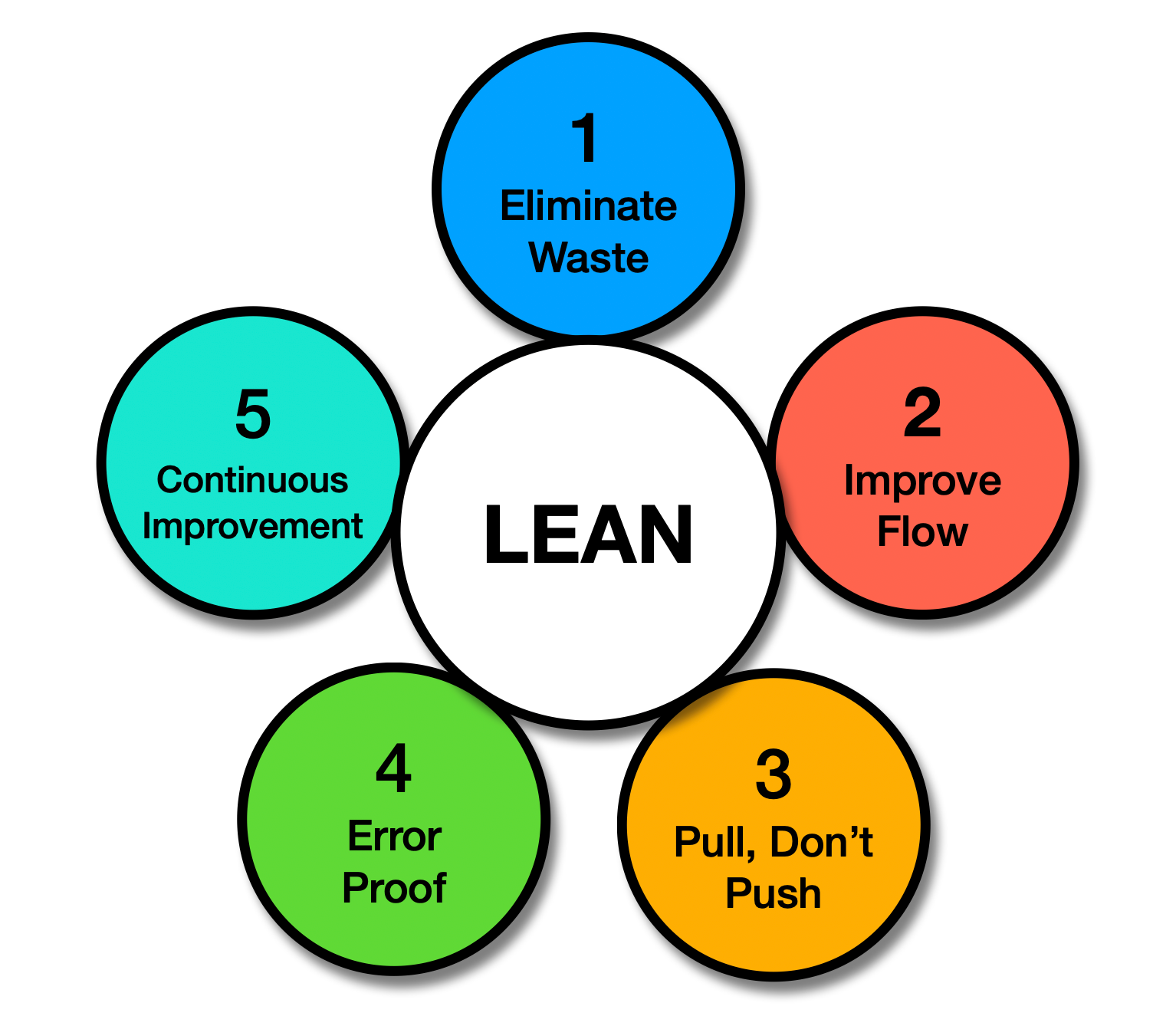

LEAN management principles, originally developed in manufacturing, provide a powerful model for addressing these challenges. Working to eliminate waste, streamline process flow, error-proof, and continuously improve, LEAN offers a way to deliver turnarounds faster, safer, and at lower cost. When combined with advanced non-destructive testing (NDT) methods, including advanced scanning technologies and mechanical properties analysis technologies, operators can transform inspection from a bottleneck into a driver of efficiency and value.

Eliminating Waste in Inspection

LEAN’s first principle is eliminating waste. In facility turnarounds, waste can frequently be seen in unnecessary repairs, redundant inspections, scaffold builds that go unused, and delays in receiving test results.

Traditional destructive testing methods for validating material properties are a prime example. Cutting out a pipe coupon to determine yield strength or fracture toughness is expensive and disruptive. Each cut can require scaffolding, welding, inspection, and requalification — easily costing hundreds of thousands of dollars per location.

NDT mechanical properties technologies offer LEAN alternatives. These portable technologies can measure yield strength, tensile strength, and some even fracture toughness directly on in-service equipment without cutting material. Property data that satisfies regulatory and engineering requirements is immediately available, while avoiding the waste of cutouts, repairs, and downtime.

For scanning technologies, Digital radiography (DR) eliminates waste compared with film-based RT, which requires processing, developing, and manual review, often forcing crews to wait hours for results. DR produces instant digital images, allowing repair crews to proceed without costly delays. And Phased Array Ultrasonic Testing (PAUT) and Automated Ultrasonic Testing (AUT) eliminate waste when compared to Manual Ultrasonic Testing (UT).

Improving Flow with Advanced NDT

Improving process flow so that work progresses without bottlenecks or interruptions is also an important LEAN concept. In a turnaround, the inspection program often dictates flow. If inspection results get bogged down, repair crews are idled, and the schedule can increase by days.

Advanced NDT methods improve flow in several ways:

- Phased Array Ultrasonics (PAUT): Rapid weld scanning identifies flaws more quickly than manual UT. Results are more reliable, reducing rework.

- Robotics and drones: Enable inspection of tanks, columns, and flare stacks without scaffolding or confined-space entry. Eliminating these prep steps accelerates workflow.

- Field-Deployed Nondestructive Mechanical Properties Analysis: Provides in situ material property confirmation. Instead of waiting days for lab results, engineers can make immediate fitness-for-service decisions.

Many of the NDT methods do not require assets to be shut down to perform their inspections. This can allow turnaround teams to shift part or even the majority of inspection work scope before shutting down equipment. This can dramatically reduce lost production time, increase safety by minimizing the time and number of staff deployed, and reduce the direct cost of inspection. This can make inspection a lever of productivity and efficiency in the turnaround schedule rather than a bottleneck, allowing smoother, faster work progression.

Pull, Don’t Push: Targeted Inspections

LEAN seeks to align work with actual demand — in other words, pull inspections based on condition, rather than push blanket requirements across all equipment.

Risk-Based Inspection (RBI) aligns well with this principle. Instead of inspecting everything equally, RBI prioritizes assets by risk and degradation likelihood. Advanced NDT strengthens this approach. Guided wave ultrasonics can rapidly screen pipelines for anomalies; only locations with indications are “pulled” into more detailed inspection such as PAUT or NDT for Mechanical Properties. This avoids the waste of over-inspection, focusing resources where they deliver the most value.

Error-Proofing with Data and Standardization

LEAN’s error-proofing principle is relevant in turnarounds. Human error in inspection interpretation can trigger unnecessary repairs, extend outage duration, or worse, miss critical flaws.

Digital inspection technologies reduce these risks. Mechanical Properties NDT, for instance, provides direct numerical outputs for yield strength, tensile strength and even fracture toughness, reducing interpretation variability between inspectors. Likewise, automated data capture from PAUT or DR integrates results directly into asset management systems, minimizing transcription errors.

Standardizing procedures for advanced NDT ensures consistency across teams and turnarounds. By error-proofing inspection, operators avoid costly rework and improve safety margins.

Continuous Improvement Through Data Feedback

Turnarounds are repeated events. The LEAN principle of continuous improvement advocates using each iteration as a learning and improvement opportunity so that the next turnaround can be better, based on its key measures of success.

NDT plays a central role in this feedback loop. Inspection findings can be compared against RBI predictions, refining future models. This tightens turnaround scopes, reduces unnecessary inspections, and improves degradation forecasting. Over time, operators evolve from reactive, broad-scoped turnarounds to leaner, data-driven events.

Case Example 1: Offshore Cost Avoidance Case

An offshore operator in the Gulf of America was scheduled to replace a piece of equipment on one of its offshore assets. The combined cost of the equipment itself, production downtime, and additional personnel time spent managing and preparing for the removal of the original equipment and installation of the new equipment was well over $10 million. Before going through with the project, the company used a NDT technology that provided the mechanical properties of the steel: tensile strength, material grade, and fracture toughness.

The result of the analysis was that the operator learned that the existing equipment was in satisfactory condition to continue operating. This allowed the company to avoid more than $10 million in cost and to avoid the significant safety and operational risk that the project would present. While not a full turnaround, this case shows the potential value of using NDT methods to prioritize repair and replacement scopes of work.

Finally, with respect to continuous improvement, the team identified the opportunity to use rope access teams in the future for the mechanical properties NDT scope, instead of building scaffolding. This could further reduce cost, improve the schedule, and expose fewer staff to safety risks.

The Next Frontier: Integrated Scanning + Mechanical NDT

While current real-world cases show automated scanning and material properties NDT being deployed sequentially, the next frontier is integration. Imagine a turnaround where:

- Automated UT crawlers scan piping welds for wall thinning and flaws.

- Digital radiography instantly flags suspect welds.

- Mechanical Properties NDT is immediately deployed on flagged areas to confirm mechanical properties like yield strength and toughness.

In this LEAN workflow, automated scanning acts as the screening layer, while mechanical properties NDT delivers asset validation at critical points. Repairs are only performed where both structural anomalies and mechanical property deficiencies are confirmed. This dual-layer approach minimizes unnecessary cutouts, accelerates decision-making, and maximizes asset life.

This integration is technologically feasible today. Operators seeking to optimize asset safety and turnaround economics should be looking closely at this combined strategy.

The Economics of LEAN + NDT

The economic case for applying LEAN and NDT in turnarounds is compelling. Operators benefit from:

- Direct cost avoidance: fewer cutouts, scaffolds, and repairs.

- Downtime reduction: faster inspection results accelerate turnaround completion.

- Life extension: Mechanical Properties NDT and advanced NDT data support continued operation, deferring capital replacement.

- Continuous improvement: inspection findings refine RBI and improve future turnaround efficiency.

When quantified in terms of avoided downtime and deferred capex, the return on investment is clear. In many cases, the cost of advanced NDT pays for itself in a single avoided day of outage.

Conclusion: A Competitive Advantage

Turnarounds will always be complex, costly, and high stakes. But by applying LEAN management principles through advanced NDT particularly automated scanning followed by targeted material properties analysis, operators can transform inspection from a bottleneck into a source of competitive advantage.

Using LEAN principles, we eliminate waste, improve flow, reduce risk through error-proofing, and use each turnaround to inform the next through continuous improvement. The result is faster, leaner, safer events that ensure mechanical integrity while protecting margins.

In a market where every day of downtime can cost millions, merging LEAN principles and advanced NDT is a strategic necessity.

Let us know your comments and questions by visiting our “Contact” page (https://www.abitechnology.com/contact-us). Thank you!